while polyurethane coated nylon fabric backed adhesive felt rolls are produced in Chinese factories,

The Benefits of Using Polyurethane Coated Nylon Fabric Backed Adhesive Felt Rolls in Chinese Factories

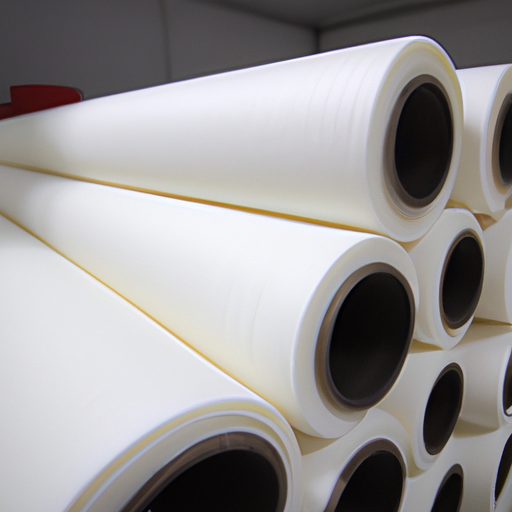

Polyurethane coated nylon fabric backed adhesive felt rolls are becoming increasingly popular in Chinese factories due to their numerous benefits. These rolls are made of a combination of nylon fabric and adhesive felt, which is then coated with a layer of polyurethane. This combination of materials provides a number of advantages that make them ideal for use in Chinese factories.

First, the polyurethane coating provides a strong and durable barrier that protects the adhesive felt and nylon fabric from wear and tear. This makes the rolls more resistant to damage and increases their lifespan. Additionally, the polyurethane coating also helps to reduce noise levels, making them ideal for use in factories where noise levels need to be kept to a minimum.

Second, the adhesive felt and nylon fabric combination provides excellent insulation properties. This helps to keep the temperature inside the factory at a comfortable level, which can help to improve worker productivity. Additionally, the insulation properties also help to reduce energy costs, as the factory does not need to expend as much energy to maintain a comfortable temperature.

Third, the combination of adhesive felt and nylon fabric also provides excellent sound absorption properties. This helps to reduce the amount of noise that is produced in the factory, which can help to improve worker safety and comfort. Additionally, the sound absorption properties also help to reduce the amount of noise that is transmitted outside of the factory, which can help to improve the factory’s relationship with its neighbors.

Finally, the combination of adhesive felt and nylon fabric also provides excellent fire resistance properties. This helps to reduce the risk of fire in the factory, which can help to protect workers and equipment. Additionally, the fire resistance properties also help to reduce the amount of damage that can be caused by a fire, which can help to reduce the cost of repairs and replacements.

Overall, polyurethane coated nylon fabric backed adhesive felt rolls are an excellent choice for use in Chinese factories due to their numerous benefits. They provide strong and durable protection, excellent insulation and sound absorption properties, and excellent fire resistance properties. These benefits make them an ideal choice for use in Chinese factories.

Exploring the Manufacturing Process of Polyurethane Coated Nylon Fabric Backed Adhesive Felt Rolls in Chinese Factories

The manufacturing process of polyurethane coated nylon fabric backed adhesive felt rolls in Chinese factories is a complex and intricate process. It involves several steps that must be completed in order to produce a high-quality product.

The first step in the process is to prepare the nylon fabric. This involves cutting the fabric to the desired size and shape, and then coating it with a polyurethane solution. This solution helps to protect the fabric from wear and tear, as well as providing a waterproof barrier. Once the fabric is coated, it is then dried and cured.

The next step is to attach the adhesive felt to the nylon fabric. This is done by using a special adhesive that is applied to the felt and then pressed onto the fabric. The adhesive helps to keep the felt in place and prevents it from slipping or shifting.

Once the adhesive felt is attached, the fabric is then cut into the desired size and shape. This is done using a cutting machine that is specifically designed for this purpose. The fabric is then rolled onto a spool and ready for the next step.

The final step in the manufacturing process is to apply the backing material. This is usually a thin layer of plastic or rubber that is applied to the back of the felt. This helps to protect the felt from moisture and other environmental factors. Once the backing material is applied, the felt is then ready to be used in the production of the final product.

The manufacturing process of polyurethane coated nylon fabric backed adhesive felt rolls in Chinese factories is a complex and intricate process. It requires careful attention to detail and precision in order to produce a high-quality product. By following these steps, manufacturers can ensure that their products are of the highest quality and will last for many years.

How Polyurethane Coated Nylon Fabric Backed Adhesive Felt Rolls are Used in Chinese Factories

Polyurethane coated nylon fabric backed adhesive felt rolls are widely used in Chinese factories for a variety of purposes. These rolls are made from a combination of polyurethane and nylon fabric, which makes them highly durable and resistant to wear and tear. The adhesive backing of the felt rolls makes them ideal for use in a variety of industrial applications.

In Chinese factories, these rolls are used for a variety of purposes. They are often used to line conveyor belts, as the adhesive backing helps to keep the belt in place and prevents it from slipping. The felt rolls are also used to line the walls of production lines, as the adhesive backing helps to reduce noise and vibration. Additionally, the felt rolls are used to line the floors of factories, as the adhesive backing helps to reduce the risk of slips and falls.

The felt rolls are also used to line the walls of storage areas, as the adhesive backing helps to keep the walls clean and free from dust and dirt. Additionally, the felt rolls are used to line the walls of production areas, as the adhesive backing helps to reduce the risk of static electricity. Finally, the felt rolls are used to line the walls of packaging areas, as the adhesive backing helps to keep the packaging materials in place and prevents them from shifting during transport.

Overall, polyurethane coated nylon fabric backed adhesive felt rolls are an essential part of many Chinese factories. They are highly durable and resistant to wear and tear, and the adhesive backing makes them ideal for a variety of industrial applications.